Mar 4, 2025 3:45:00 PM

Manufacturers of sports supplements, nutraceuticals and powder-based dietary..

Quadro Engineering is the trusted provider of powder processing equipment to nutraceutical manufacturers for particle size reduction and milling processes.

Whether it is a dietary supplements, a powder blend, or vitamin tablets, our nutraceutical milling equipment ensures your ingredients are correctly sized in significantly less time when compared to conventional methods.

Our milling and particle processing equipment has been expertly designed to handle the raw and processed materials used in dietary supplements, health foods, and other nutritionally rich nutraceutical products.

To prepare both the raw material and powdered ingredients used in nutraceutical supplements, the methods of milling, sifting, deagglomeration and/or delumping can be applied. This ensures that the ingredients for your recipes are in the correct forms and particle size to suit the formulation and to meet the required conditions for integration into various delivery methods.

As many nutraceutical products typically contain a bioactive compound to provide therapeutic and health benefits, accurate particle size reduction and formulation integrity are essential to ensure the correct bioavailability and consumption of active ingredients.

Manufacturers of nutraceutical products face many challenges due to the nature of the product requiring a reliable dosage and safe for consumption.

Key considerations when manufacturing nutraceuticals include:

These are important not only for consumer safety but also to retain customer loyalty with a reliable, effective product in a highly competitive market.

Nutraceutical production facilities must also be flexible so that manufacturers can remain agile and respond to changes in consumer trends and regulations.

With these requirements, developing a reliable and flexible nutraceutical processing system can create many challenges, especially if the powders exhibit poor flowability and/or compressibility.

A focus on the bottom line means that a strong financial payback on any equipment investment is necessary.

Quadro Engineering has vast experience in providing milling and sizing solutions for manufacturers of nutraceuticals and functional foods, that are backed by pharmaceutical standards with food know-how.

Our team has 45+ years of experience in powder processing and can recommend the right milling equipment, screen sizes and settings to improve production efficiencies based on our extensive experience gained working globally in both lab and production facilities.

Quadro leads the market in designing and manufacturing nutraceutical milling equipment. Our product offering, experience and reliable support to a diverse array of businesses enables them to substantially minimize product loss and enhance manufacturing cost efficiency.

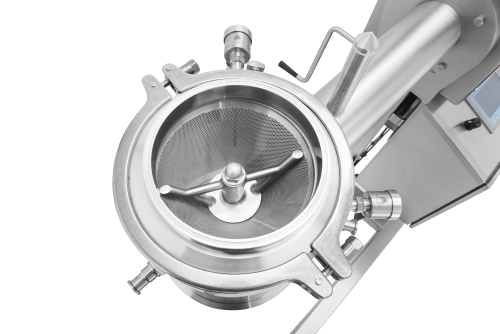

At Quadro, we are ready to assist you with our powder processing and particle size reduction solutions. Our patented equipment and unique screen design ensure a precise particle size distribution, crucial for achieving your desired material parameters.

Drawing from our extensive experience as a leader in the pharmaceuticals and food industries, we possess a deep understanding of the essential properties and conditions required to manage various drug therapies and nutritional supplements. We are well-versed in meeting the rigorous regulatory standards of good manufacturing practices in the most demanding environments. Our particle size reduction equipment is highly regarded by top nutraceutical manufacturers globally and adheres to the strict hygiene standards established within the industry.

When you invest in Quadro® Nutraceuticals Milling Equipment, you get more than just superior machines, you get access to our team of experts who will ensure you achieve your objectives.

We offer industry-leading milling, screening and particle size reduction equipment for manufacturers of nutraceuticals, health supplements, and functional foods. Our equipment is designed to meet exacting FDA cGMP standards for the safe processing of pharmaceutical and nutraceutical powders and food ingredients.

The unique greaseless sanitary gearbox housing of our equipment offers batch reliability by mitigating the risk of contamination and reducing the operating temperatures which protect heat-sensitive ingredients. The simplicity of this design streamlines cleaning procedures, thereby reducing planned maintenance downtime.

Our applications experts can help you solve your size-reduction and powder processing challenges, whilst meeting any control standards. Get in touch to increase your production effectiveness.

We provide top-tier milling, screening, and particle size reduction equipment tailored to comply with stringent FDA cGMP standards. Our team of application experts is ready to assist you in overcoming your powder processing challenges and enable you to enhance your production efficiency. Get in touch using the form below.

With our decades of experience, we have expertise in providing a wide range of effective powder processing solutions. From fine powder grinding to security screening, we can help you find the equipment to meet your needs.

Recommended downloads for nutraceuticals manufacturers.

The world's most advanced benchtop multi-purpose powder milling and screening platform.

Innovative milling, sifting and size reduction technology, offering multiple powder processing solutions on one platform.