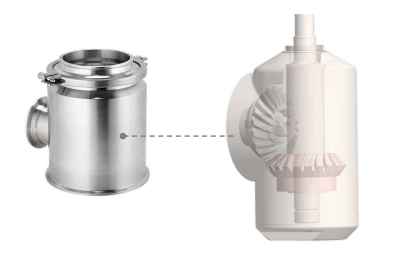

Our new SDx SeriesTM common drive platform features an innovative greaseless gearbox design within the U20x and S20x heads. The World’s first and only (patent-pending) conical mill greaseless gearbox.

Mitigate against product contamination

The conical mill greaseless gearbox gives users the peace of mind that product integrity is maintained at all times, with no possibility of grease leakage or contamination that could occur with traditional designs.

We have seen mills in the past where the shaft seal became worn or was inadvertently damaged, which resulted in grease seeping through into the product. Although not a common occurrence, and one that users can mostly prevent with good cleaning SOPs and regular maintenance programs, it is nevertheless a potential area of concern.

By way of example, if a seal was damaged during cleaning from the use of sharp tools (which are of course not recommended in the owner’s manual, but something that we have seen happen from time to time), moisture during cleaning may get past the seal’s line of defense. Thereafter, on subsequent batches, as the grease in the gearbox heats up and mixes with moisture, it could lead to this substance escaping back into the product itself – rendering the entire batch unusable.

Taking a conservative estimate, this discarded batch could represent $250k in lost revenue, not to mention the costs involved with securely scrapping the batch and having to make a replacement one to meet production targets.

At this point, the availability of a greaseless gearbox becomes that much more important.

Low heat milling

A further benefit is that the greaseless gearbox operates at approximately 50% lower temperature. This is a far cooler temperature than mills that are driven by constantly lubricated gearboxes.

This creates a much cooler working environment and more consistent results, which enables users to process heat-sensitive products more successfully.

cGMP compliant milling equipment

Improved gearbox design facilitates serviceability and increases longevity over traditional gearboxes. Refreshed cGMP design of gearbox housing simplifies access

to internal components and reduces complexity, thus decreasing planned maintenance downtime.

Testimonial

North American Pharma OSD Company changed equipment to a greaseless Comil and reduced temperatures during milling of heat-sensitive powders.

“This is a very nice piece of equipment. I am pushing to get another one as I think these would be good to have on site for future projects”. Process Engineer.

In summary

The new Comil® U20x and FlexSift S20x Gearbox design offers:

- Improved serviceability and ease of proactive maintenance with an easy-to-replace shaft seal design preventing unwanted downtime.

- Greaseless gearbox design eliminates the risk of grease contamination.

- Drastically lowered running temperatures for improved processing of heat-sensitive materials.

- Reduced operating levels by 5-10 dB (< 75 dB vs < 82 dB).

- CIP, SIP and Autoclavable gearbox design all in one.

- Increased longevity over traditional gearboxes with unmatched engineered safety factor.

Retrofitting new technology

We are also delighted to bring the benefits of this new SDx SeriesTM technology to the Classic Quadro mills currently in use.

We have designed a multi-compatible greaseless gearbox solution that enables easier maintenance and extends the life of existing equipment.

Retrofitting existing U20 and S20 models not only increases the peace of mind the greaseless gearbox provides, but by reducing the number of variations of previous generations of designs our customers can simplify their maintenance strategies and stock a one-design-fits-all assembly.

Learn more with our test results

If you are interested in learning more about the greaseless gearbox or would like to see how it compares to standard steel gears, we'd be happy to share our test results with you on a call.

Quadro's team is also happy to help identify the correct adapter for your machine and supply all parts for a correct fitting – simply contact us to find out more