HOME / TECHNOLOGY / ATEX MILLING

ATEX Compliant Milling Equipment

Minimize risk when purchasing, commissioning and operating

milling and sizing equipment.

What is ATEX

How safe an ATEX-marked mill is, should never have to be questioned. With the guidance and certification from a European Ex-notified body, powder size-reduction equipment manufacturers can address certain ignition sources – like mechanical sparks in mills – and clearly outline Special Conditions of Use to ensure a safe engineered solution is supplied when milling powders.

The ATEX directive is 100% geared towards the avoidance of a dust or gas-based fire or explosion – potentially putting operators, equipment, and facilities at risk.

Ignition and hazard assessment – where it all begins

The “ATEX Directive” is comprised of two European Directives: 99/92/EC, known as the “ATEX - Worker Protection” Directive and the new 2014/34/EU Directive, known as the “ATEX - Equipment” Directive.

The ATEX “Worker Protection” Directive is directed at the equipment Owner. Under Article 4, the equipment Owner is obligated to assess explosion risks in their facility. This includes conducting a hazardous area classification also known as “Zoning” (see Table 1).

Equipment for Potentially Explosive Atmospheres (ATEX)

The Atex Directive for Equipment Owner - Working Protection

The first step to reducing the risk of a dust explosion in any milling operation is to identify all potential ignition sources; then determine if each ignition source is likely to be present during “normal” operation, during an “expected” malfunction or during a “rare” malfunction; and finally, identify the measures taken to prevent the potential ignition source from becoming effective.

In the case of a mill, there are four potential types of ignition sources: electrostatic discharges; hot surfaces; mechanical sparks; and electrical sparks.

| Zone | Zone Definition | Equipment Category | Protection Level (Relative Cost) |

Certificate Requirement |

||

| Gas (G) | Dust (D) | Gas (G) | Dust (D) | |||

| 2 | 22 | Explosive atmosphere not likely to occur in normal operation, but if it does occur, will persist for a short period only | 3G | 3D | None | Manufacturer’s Declaration |

| 1 | 21 | Explosive atmosphere likely to occur in normal operation occasionally | 2G | 2D | Low ($) |

Manufacturer’s Declaration |

| 0 | 20 | Explosive atmosphere likely to occur in normal operation occasionally | 1G | 1D | Medium ($$) |

Manufacturer’s Declaration |

* Table 1. Equipment Protection Level and Category for each Zone.

ATEX Directive for Equipment Manufacturers - Four Steps to Minimize Risk

To minimize risk when purchasing, commissioning and operating milling equipment with combustible powders, the following steps are imperative:

- Know the Ignition Sensitivity of The Powder.

Some powders are much more ignition sensitive than others, therefore two key parameters need to be known: the Minimum Ignition Energy with inductance (MIE1mH) and the Minimum Ignition Temperature of the dust cloud (MITcloud). - Review the EU Type Examination Certificate, Special Conditions of Use, and Residual Risks.

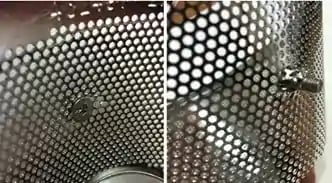

When purchasing a mill, be sure to ask the manufacturer for the “Specific Conditions of Use” (or Restrictions of Usage), and any residual risks from the ignition hazard assessment. Ask if foreign objects have been considered in the risk assessment (Fig 1), and insist on seeing the ATEX markings on proposed mills, and the EC (or EU) - Type Examination Certificate for any Category 1 mill before purchasing.

Fig 1: Screw embedded in the screen during powder processing in a conical mill

The mill supplied should be able to list the various Restrictions of Usage based on the Mill’s Category and/or Zoning and the Protection Methods proposed. If the manufacturer is unwilling or unable to supply this information, it may be advisable to decline the purchase and contact an alternate mill vendor. - Decide if Inertion or a Pressure Shock Resistant Mill is Required.

If small foreign objects cannot be excluded with 100% confidence for a mill rated for 1G or 1GD internal zoning, expert opinion agrees inert or PSR design the mill. Speak to our team about what Protection Methods and/or Restrictions of Usage are required for 1D, 2GD/3GD internal zonings. - Review the Instructions and Conduct Operator Training.

Review all operating instructions and warnings in the mill’s manual and conduct training with the users and maintenance staff to ensure they understand what is required to safely operate and maintain the mill. If additional support is required, consult the mill vendor for available on-site training programs.

Why Do You Need ATEX Rated Mills & Sizing Equipment?

The ATEX Directive was introduced to ensure the safety of operators and equipment. Even if the likelihood of an explosion within a mill is remote, the potential for one is still present.

It is the paramount responsibility of any ATEX mill manufacturer to supply safely designed equipment, clearly communicate all Special Conditions of Use (Restrictions of Usage), residual risks, and warnings to not compromise operator or facility safety.

It is the responsibility of the equipment Owner to understand the ignition sensitivity of their powders; inert or PSR design the mill If necessary; scrutinize all the Special Conditions of Use and warnings and train the users how to safely operate and maintain the equipment.

You should always ask your mill supplier if there is any doubt about the engineered solutions they offer with ATEX-rated mills. This is in your best interest. Investigate, question, and challenge your mill vendor, and in combination with the steps outlined in this article, it will help to greatly minimize the risk of an explosion when acquiring, commissioning, and operating a mill for combustible powders – ensuring your ATEX mill is safe!

DO YOU NEED ASSISTANCE?

Stay Safe and Informed With Quadro

You can rely on Quadro to help you operate safely, reliably and efficiently when working in a potentially explosive atmosphere. If you'd like further information on ATEX milling or any of our equipment, please get in touch.

ATEX Rated, Contained (Dust-Free) Milling

Our ATEX Approved Milling and Sizing Equipment is used globally by manufacturers of all sizes in the food, nutraceutical, chemical, and pharmaceutical industries.

The Scalable Lab System™ (SLS)

MILLING & SIZE REDUCTION

One platform with five milling, size reduction, and processing solutions.

The SLS Scalable Lab System™ gives the reassurance that particle sizes and distributions achieved in the lab can be directly transferred to the production-scale equipment.