Quadro

Resource Centre

Gain advice and best practice on Quadro’s milling and particle size reduction technology by viewing our application bulletins, technical videos and brochures.

Gain advice and best practice on Quadro’s milling and particle size reduction technology by viewing our application bulletins, technical videos and brochures.

Milling

The G96 Food Mill is designed for gentle milling of process-sensitive food ingredients. Watch this video to learn how this mill can used to mill cookies for reclaim.

Milling Lab-scale

Discover the Scalable Lab System™ (SLS), the world's most advanced bench-top, multi-purpose powder milling and screening platform.

Milling Lab-scale

Find out how you can achieve unparalleled milling flexibility and improved powder processing efficiency in a lab-scale environment.

Milling Lab-scale

Easily interchange between Fitzpatrick’s FitzMill™, Quadro’s Comil® conical mills and FlexSift Security Screening technologies.

Milling Production-scale

Discover the SDx™ Series, the world's first production-scale milling and security screening platform offering three distinct powder processing solutions on a single, common drive.

Milling Pilot-scale Mid-size/range

The industry's most progressive mid-sized milling and screening platform offering two pilot-scale processing solutions on a single, common drive.

Milling Production-scale

Introducing our next-generation innovation in size reduction and powder milling technology, combining multiple powder processing solutions on one platform.

Milling Pilot-scale Mid-size/range

The world's first mid-size/pilot-scale milling & security screening platform with two distinct powder processing solutions on a single, common drive.

Milling Production-scale

Find out how you can achieve unparalleled milling flexibility and improved powder processing efficiency in a production-scale environment.

Milling Pilot-scale Production-scale Lab-scale Mid-size/range

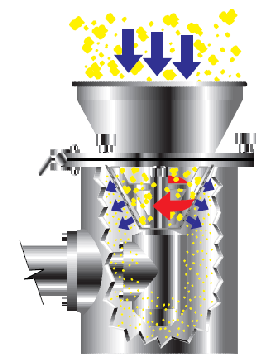

The Overdriven Cone Mill offers high capacities, narrow particle size distributions and is fully scalable from R&D to large production volumes with accuracy and repeatability of results.

Fine Grinding

An all-in-one fine powder grinding machine, delivering the highest percentage within the target PSD of any fine milling technology.

Milling Production-scale

Produce more uniform particles in a fraction of the time by switching to an inline Quadro® Comil®.

Milling Production-scale

The installation of an inline Quadro® Comil® more than doubled the original capacity of their dry granulation process.

Milling Production-scale

Used in a variety of applications throughout the pharmaceutical industry, the Quadro® Comil® is the perfect partner for delumping, mixing, finishing and milling.

Milling Production-scale

Achieve shorter drying times of cannabis CBD isolate by ensuring all the particles are a consistent, small size. Find out how by downloading our application note.

Sifting Production-scale

How a sports protein powder manufacturer eliminated the appearance of agglomerated material and saved money on wasted product using the Comil®.

Milling Production-scale

In this application, a Comil® is used to break open powder filled gelatin capsules without damage and extract the expensive active powder contained within for recycling.

Milling Production-scale

Overcome the challenges faced by manufacturers of metallic pigments to properly size component particles to meet specific flow characteristics.

Milling Production-scale

See how a Quadro® Comil® can help you achieve a consistent and predictable particle size to maximize yields from the cannabis plant, whilst maintaining product quality.

Milling Production-scale

The Quadro® Comil® is the ideal solution to reclaim and reprocess tablets as the flexibility in screen and impeller choice means they can be matched to the task in hand.

Milling Production-scale

The Comil® can accept direct feed from a mixer and condition powders correctly for efficient manufacturing, removing lumps from wet masses before the drying process.

Milling Production-scale

Create a powder that is flowable, free from agglomerations and has the correct particle size distribution with a Quadro® Comil® and FlexSift®.

Milling Production-scale

Decorative toppings or inclusions used in the dairy industry can be difficult to handle as they are heat sensitive. Read how the Comil® offers reliable, robust and 3A compliant designs.

Milling Fine Grinding Sifting

Discover our state-of-the-art testing and development centre, featuring an extensive range of lab and production equipment.

Milling

The G96 Food Mill is designed for gentle milling of process-sensitive food ingredients. Watch this video to learn how this mill can used to mill cereals.

Milling Lab-scale

The SLS allows users to instantly switch heads without the need to manually reset control parameters for effective lab-scale milling.

Milling Lab-scale

The SLS - Scalable Lab System™ provides the ability to alternate between five powder processing solutions in seconds.

Sifting Production-scale Lab-scale Mid-size/range

Revolutionary high-capacity centrifugal sifting equipment for effective deagglomeration of raw materials and security screening.

Milling Production-scale

SMARTdetect™ technology built into the SDx™ Series platform allows users to instantly switch heads with no need to manually reset control parameters.

Milling Production-scale

Production-scale interchangeable powder milling and screening. Utilizing one common drive with a series of interchangeable heads.

Milling Production-scale

Guarantees full cleanability with very simple disassembly assuring 100% cleaning verification. Varied screen sizes available.

Milling Production-scale

The Comil® U20x head for conical milling improves particle size distributions (PSDs) with 20-40% more on-target vs similar technologies.

Type your question for our team below.

Quadro Engineering, a division of IDEX MPT, Inc has earned the respect & trust of customers worldwide through our commitment to improving the performance of their powder processing operations. We set the standards by which others are measured.

© Copyright IDEX 2026

To ensure you make the most of your equipment, we offer a comprehensive range of spares, maintenance, and support packages.

› Contact usThe information you provide will be sent to the relevant team.

Existing Customer? Please contact our team via the Aftermarket Page