Would you like to have an easy-to-use reference document that shows which mill or screen will achieve your desired particle size?

Achieving the target particle size at a tight particle size distribution is vital in producing a quality product no matter what industry you are operating in. For the Pharmaceutical sector, it affects things like drug efficacy and tablet integrity; in the Chemical industry it influences pigment coloration and safety of chemicals and in the Food industry, the powder particle size will influence taste and texture.

Besides quality, the right sized particle saves you money. Higher yields with on target particles will produce higher yields per labor hour, reduce batch waste and reduce reclaim processing. In drying applications particle size is critical to reducing dry times, hence reducing expensive energy costs.

Choosing the right Mill to achieve target particle sizes

Cone Milling (or conical milling), and Hammer Milling are widely used milling methods in these industries. Selecting which milling process to use ultimately depends on the target particle size trying to be achieved.

Quadro Engineering and the Fitzpatrick company are both part of the IDEX Materials Processing group and jointly have more than 120 years of experience in powder processing and milling. With more than 40,000 equipment installations we have earned the respect of our customers around the world. Our highly experienced teams of professional consultants and sales engineers help our customers to determine their goals and then ensure the right mill is selected.

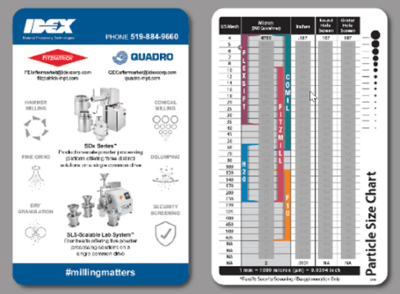

Particle Sizing Card for Milling

It is not just about the mill, but the screen type and impeller that are selected too. We help our customers to understand what is possible by sharing what we call our ‘Particle Size Card’ - this sizing chart ties the target particle size to the mill type and the size of round or grater hole screen required in partnership. Armed with the Particle Size Card, you’ll be able to work with our team to achieve the exact PSD you need.

Our team takes the conversation further and for each type of particle or powder, they also evaluate if any special coatings are needed, and of course look at the RPM and tip speed, to mill your product and achieve your specified PSD.

A wide range of mill screen types and sizes

We have the largest range of screens and impellers available with screen openings available between 0.150mm (0.006”) and 38mm (1.5”). Screen types include round and square perforations, wire mesh, and grater (or Conidur) holes.

There are dozens of profiled impellers designed to suit exact requirements including basic versions with round, square or beveled arms, and more aggressive profiles. Impellers can be further customized with special add-ons and finishes.

Effectively scale up from lab to pilot to production

We’ll help you navigate through the choices of screens and impellers and match your product with the perfect tip speed to achieve consistent and scalable PSD results.

When this set of parameters is set, you’ll not only be able to accurately achieve the PSD you need, you’ll also be able to quickly scale up from lab-sized equipment to full-capacity production using those exact same operating parameters.

Learn more about PSDs with our article: The Importance of Particle Size Distribution in Pharmaceuticals

How do I get the Quadro and Fitzpatrick Particle Size Chart?

Fill out the form below to give us your contact information and a member of our team will send you a copy of the card. If you have any further questions or would like to arrange for a demonstration you can use the contact information on the card to contact us using the form.